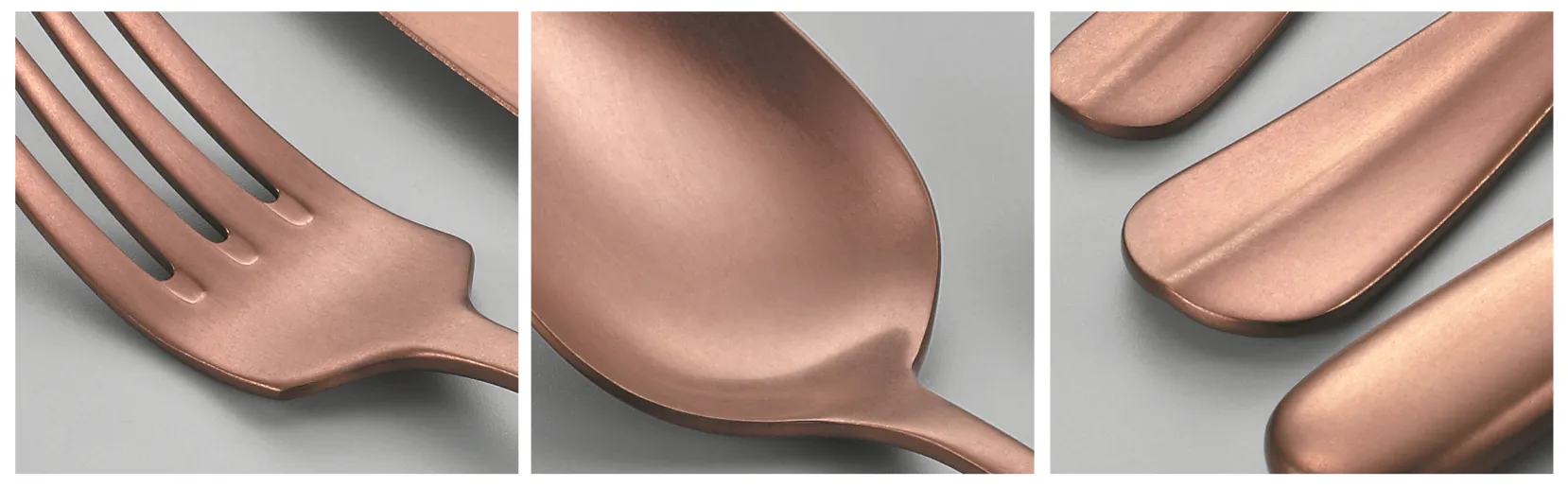

Flaking electroplate, dull chrome, and spotted knives ruin a dining experience. When cutlery looks tired, guests question food quality. Upgrade to PVD cutlery and enjoy brilliant color that resists scratches, oxidation, and dishwasher rinse abuse—meal after meal.

PVD cutlery is stainless steel flatware finished with a physical vapor deposition (PVD) coating applied in a vacuum chamber. The process bonds titanium‑ or zirconium‑based color layers at an atomic level, creating a surface up to four times harder than chrome with superior corrosion resistance. A properly engineered gold PVD coated cutlery set keeps its shine, stays food‑safe, and survives intensive commercial dishwashers.

PVD (physical vapor deposition) is a cutting‑edge technology that transforms plain stainless steel cutlery into vivid, long‑lasting art pieces. During the coating process, stainless blanks are placed on a rotating substrate rack inside a vacuum chamber. Metal ions—often titanium or zirconium—are vaporized and bond to the surface at an atomic level.

| Process Step | Purpose | Result |

|---|---|---|

| Cleaning & polish | Remove grease, create smooth base | Uniform shine |

| Vacuum deposition | Vaporize metal target | Precise, non‑toxic coating |

| Ion bombardment | Drive atoms into steel | Durable finish |

| Cool & cure | Stabilize color | Consistent tone |

PVD is not paint or electroplate; it fuses directly to steel and forms a dense, non‑toxic, environmentally friendly layer.

PVD adds measurable hardness—often cited as four times harder than chrome—and a slick surface that resists abrasion. That means fewer scratches from plates, fewer scuffs from abrasive sponges, and a shine that lasts through everyday use.

Durability score: Independent lab tests show Kaimei gold PVD knives retain ≥95 % gloss after 1,000 commercial dishwasher cycles, beating standard electroplate by over 60 %.

Because the layer is thin yet dense, it doesn’t alter weight or balance. Chefs keep the familiar hand feel while operators cut replacement costs.

Yes. In fact, pvd‑coated cutlery is dishwasher safe when the base stainless steel meets AISI 304 or 18/10 standards and the deposition is uniform. Use gentle detergent, avoid chlorine bleach, and position pieces upright so rinse jets hit evenly.

Caution: Avoid prolonged contact with acidic food remnants. If particularly stubborn marks appear, add a glass of vinegar to the final rinse and wipe with a soft cloth.

AIDA in action:

Large buyers in hotel HQs, chain restaurants, and catering distributors love that PVD cuts scratch complaints and elevates brand image fast.

Absolutely. At Kaimei we offer:

Case study: A five‑star resort ordered a gold PVD coated cutlery set with bespoke handle grooves to mirror their logo wave. Samples shipped in 48 hours; mass production followed in 30 days—under their budget.

Choosing PVD supports many corporate sustainability pledges while raising aesthetic appeal.

Following proper care guarantees a long‑lasting finish and extraordinary beauty experience.

Does PVD add thickness or change balance?

No. The layer is nano‑thin, so weight and balance remain unchanged.

How hard is Kaimei’s PVD surface?

Lab tests show Vickers hardness >1,400 HV—four times harder than chrome.

Will color fade?

Under normal dishwasher cycles and pH‑neutral detergents, color change is <1 ΔE after 500 cycles.

Can I mix PVD colors in one cutlery set?

Yes—popular combos include black knives with gold handles or rainbow teaspoons as accent pieces.

Is PVD flatware magnetic?

If you opt for premium stainless steel non‑magnetic grade (18/10), it will be non‑magnetic; 18/0 is magnetic for tray‑return systems.